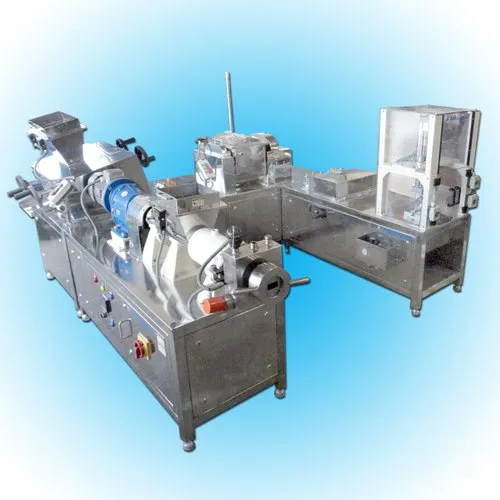

Pilot Soap making machinery Manufacturer

We produce Machinery specifically created for small-scale or pilot-scale soap production are referred to as pilot soap making machinery. usually soap producers or people who need to make soap in smaller amounts for testing, research and development, or limited production before growing to bigger production processes utilise such equipment.

It's necessary to keep in the mind that the particular machinery needed for detergent producing can vary based on the procedure used to make the soap, the components used, the type of good wanted, and the rate of production. Pilot soap-making machinery is often made to be movable, adaptable, and simple to use in order to meet the needs of smaller-scale production.